Deep Energy Retrofit Decarbonization Planning

Treehouse at Easthampton Meadow

Location: Easthampton, MA • Size: 60 units in 23 low-rise residential buildings plus a community building and a maintenance building • Developer: Beacon Communities • Owner: Treehouse Foundation • Owner’s Representative: Waypoint KLA • Architect: Davis Square Architects • Mechanical Engineer: Petersen Engineering • Contractor: Keith Construction

PROJECT BACKGROUND

The Treehouse at Easthampton Meadow (Treehouse) is an intentional, intergenerational community that integrates family housing for households who have adopted children out of the foster system with households aged 55+ who agree to mentor the children. Originally built in 2006, the development is approaching a tax-credit supported refinance process that will enable retrofit/improvement of the buildings. New Ecology worked with the project design team to develop a data-driven deep energy retrofit scope of work for the property that maximizes energy and carbon emissions reductions, eliminates fossil fuel consumption, improves resident comfort and indoor air quality, and works within the financial limitations of the retrofit project budget and available operating resources.

Beacon Communities is an affordable housing developer, owner, and manager that is committed to leveraging building retrofits to improve the performance and comfort of their properties. Their approach to building decarbonization aligns well with federal, state, and local policy priorities for reducing emissions in existing buildings, improves the project’s competitiveness for Low Income Housing Tax Credits (a critically important financial resource), and makes the project eligible for an increasing number of state and utility funding and incentive programs targeted for affordable housing projects that aggressively reduce emissions and improve building performance, comfort, and health outcomes.

SOLUTIONS AND FEATURES

Deep Energy Retrofit Scope Development Process

To determine the best approach for retrofitting the development, the team engaged in a highly integrative investigation and evaluation process that prioritized a deep understanding of the existing conditions and performance of the buildings. Packages of energy conservation and electrification measures were considered based on a number of important evaluation criteria

(see list to the left), with careful attention paid to leveraging the experience and expertise of the design team to streamline the number of different packages requiring pricing and energy calculations for informed decision making. The process included:

- A kick-off meeting to define goals and process

- Building performance benchmarking using historical utility data

- Building inspections/audits, air infiltration blower door testing, and operations team interviews

- Renewable energy analysis

- Integrated design team meetings to review preliminary findings, evaluate opportunities and limitations, and narrow down retrofit options/approaches

- Development of a Conceptual Design Narrative with preliminary retrofit approaches for energy calculations and cost estimating

- Integrated design team meetings to review results of energy calculations and cost-estimating and refine project retrofit approach

- Revised energy calculations and cost estimating to determine the scope of work that achieves cost and performance goals

Selected Retrofit Measures

Using the process outlined above, the team decided on the following set of Deep Energy Retrofit measures:

- Added exterior wall insulation (R-8 mineral wool)

- Roof insulation retrofit (conversion to 6” closed cell spray foam at the underside of roof sheathing)

- Window replacement (U=0.25, SHGC = 0.30)

- Building envelope air sealing (target 2 ACH50)

- Conversion of gas furnaces to electric air source heat pumps (18 SEER, 3 COP)

- Conversion of gas to electric resistance domestic hot water heaters (to eliminate fossil fuel)

- LED lighting upgrade

- Efficient toilets and faucet aerators to deliver water savings

- Energy Recovery Ventilators (ERVs) to improve indoor air quality (88% heat recovery)

Selection of the domestic hot water system proved to be a challenge given competing priorities. Implementation of electric heat pump water heaters would have increased the energy savings and reduced the carbon emissions and operating utility cost of the development, but came with a significant increase in capital cost and design challenges.

Maintaining a gas-fired system would have reduced operating utility cost and energy savings but would have kept the development from realizing its fossil fuel free goal. The team decided to prioritize electrification of the system and the future emissions reduction potential of the grid by implementing an electric resistance approach.

The team also investigated the application of photovoltaics at the development, but due to limited south facing roof area and tree shading, opportunities are limited. The team decided to revisit the feasibility of incorporating renewable energy at a later date for the community building specifically.

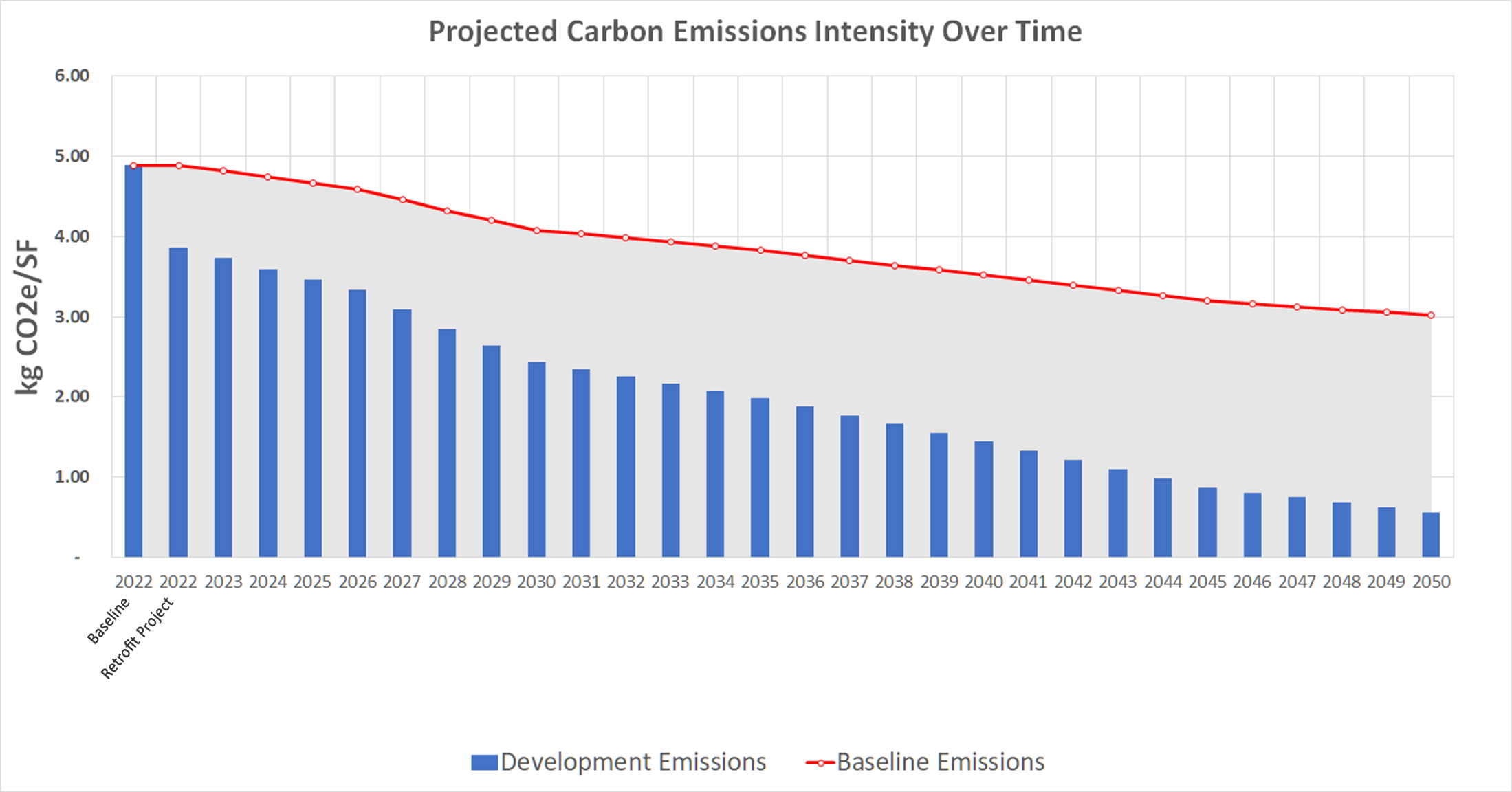

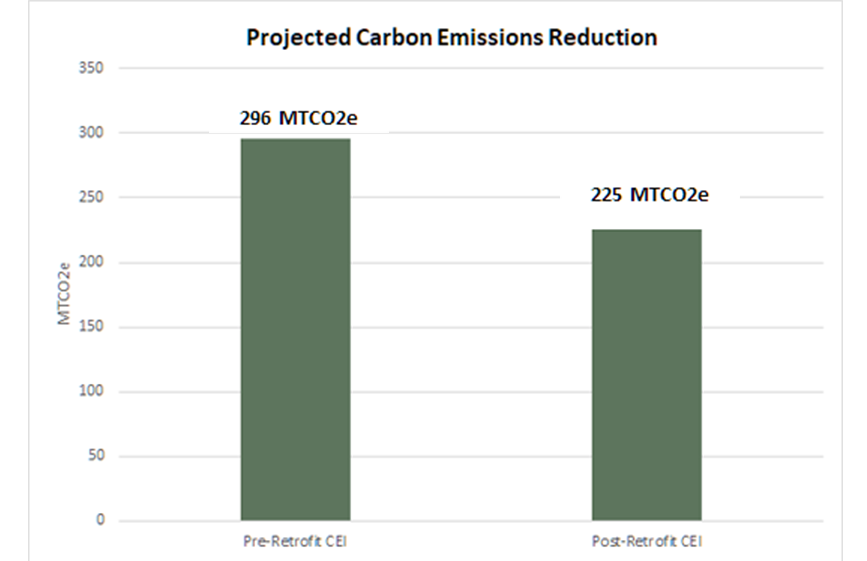

Note on graphs: Carbon Emissions calculated using The National Renewable Energy Laboratory (NREL) Cambium’s data (Electric) 2022 NREL Cambium Dataset – LRMER; NEWE Grid – Midcase w/ 95% Decarbonization by 2050 Combustion + Precombustion.

Reducing the overall emissions impact of the retrofit project by careful attention to the embodied carbon impact of specific materials and components was a priority for the project team. Careful attention was paid to ensure that components/systems that still have useful life, were not adversely impacting energy use, and can be easily replaced later (such as the roofing) are not replaced prematurely. Reuse of existing duct work and deconstruction/reuse of the existing vinyl siding on the buildings will also happen wherever possible. For materials that must be specified to achieve energy performance goals (i.e. exterior insulation), the team investigated and implemented the lowest embodied carbon materials available that worked within project technical and funding limitations.

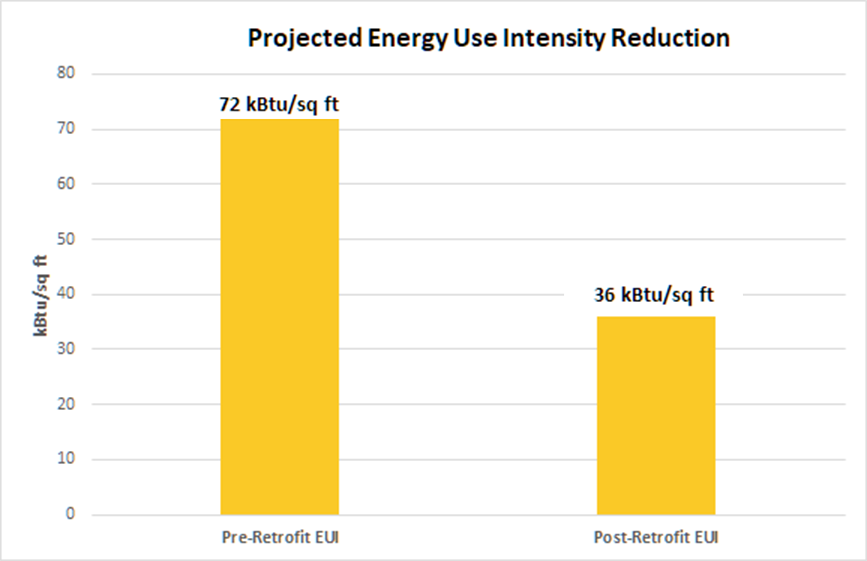

Integration of the selected measures is predicted to significantly reduce energy consumption and carbon emissions at the site. Electrification of the HVAC systems at the development will further facilitate emissions reductions over time as the carbon intensity of the electric grid improves.